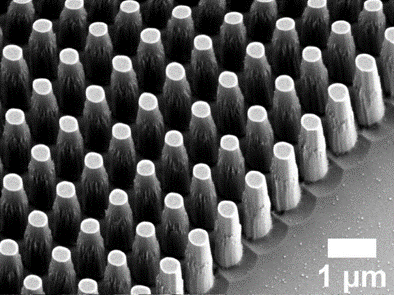

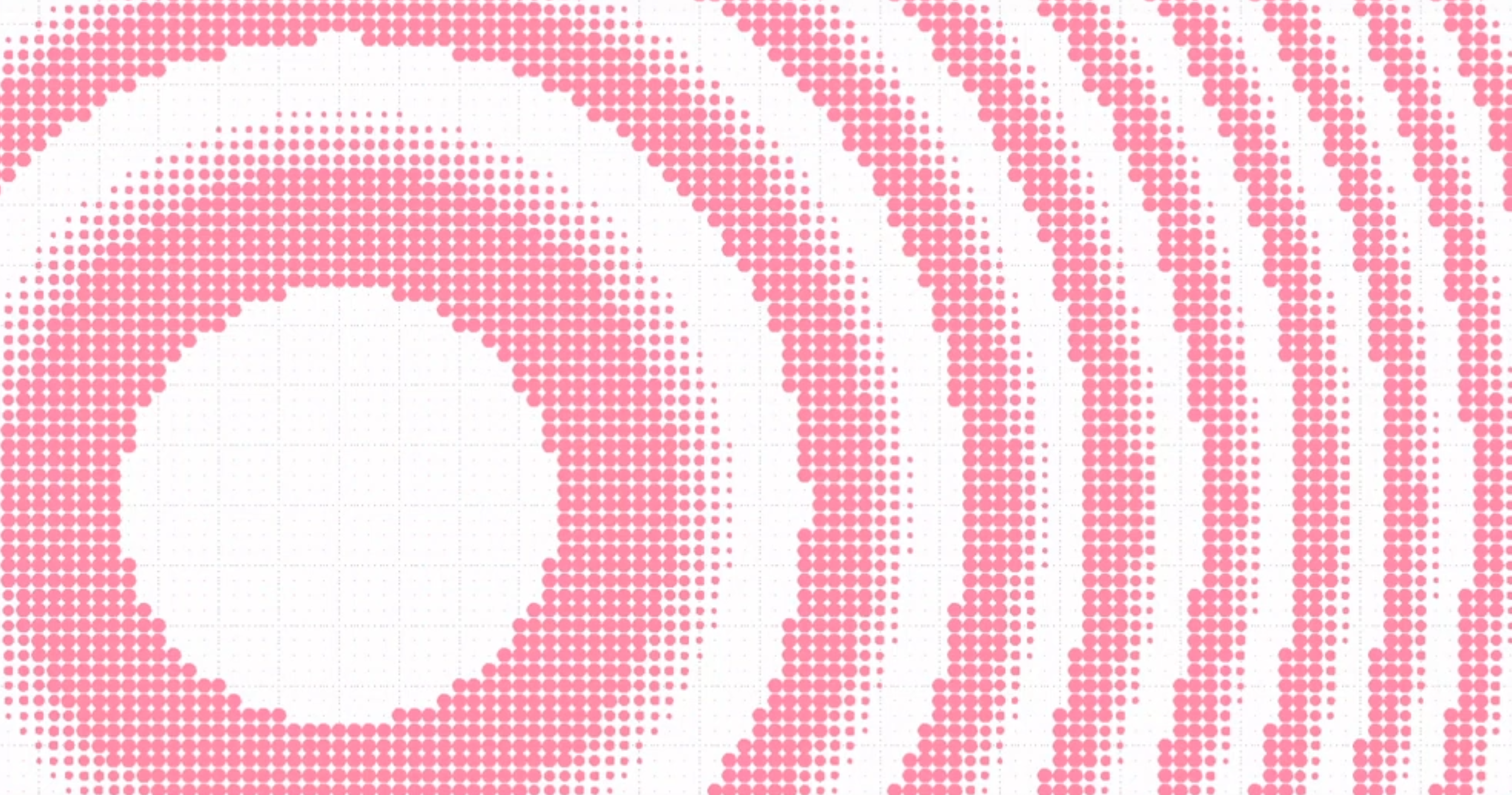

round pillars

polarization insenstive

polarization insenstive

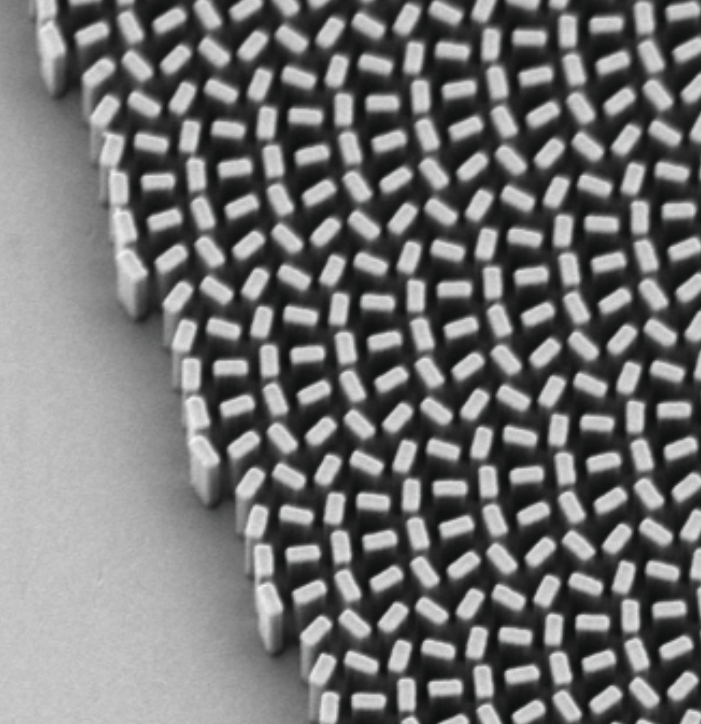

rectangular pillars

for circular polarization

for circular polarization

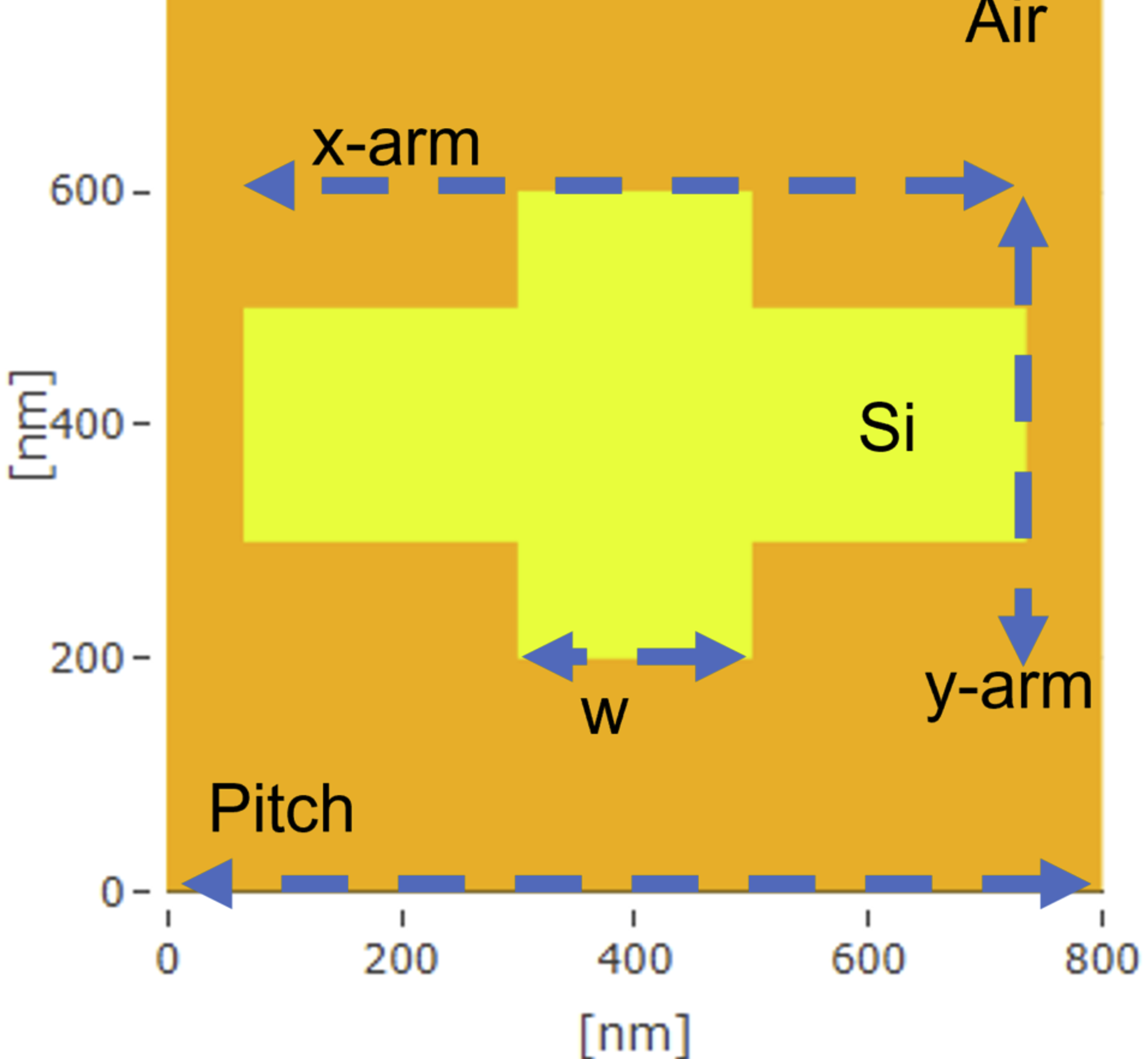

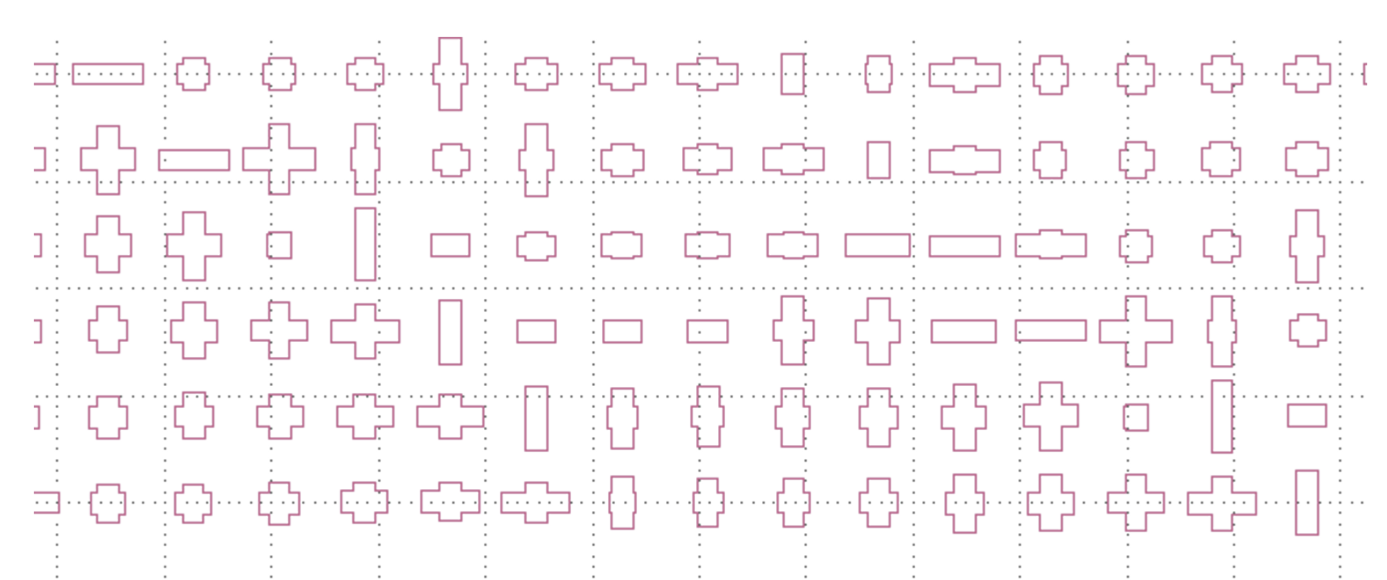

cross-type pillar

x-arm length TM polarization

y-arm length TE polarization

x-arm length TM polarization

y-arm length TE polarization

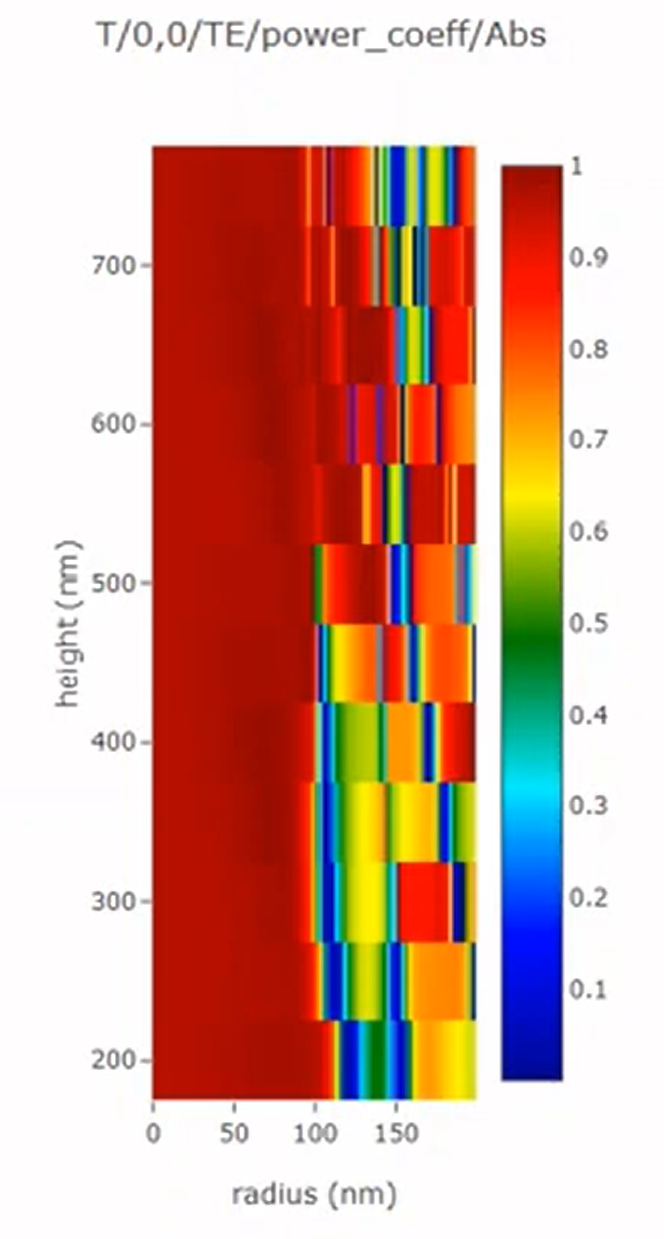

heat map plot showing

transmission vs pillar height

calculated using RCWA

Pillar height selected for

good transmission across

pillar radii

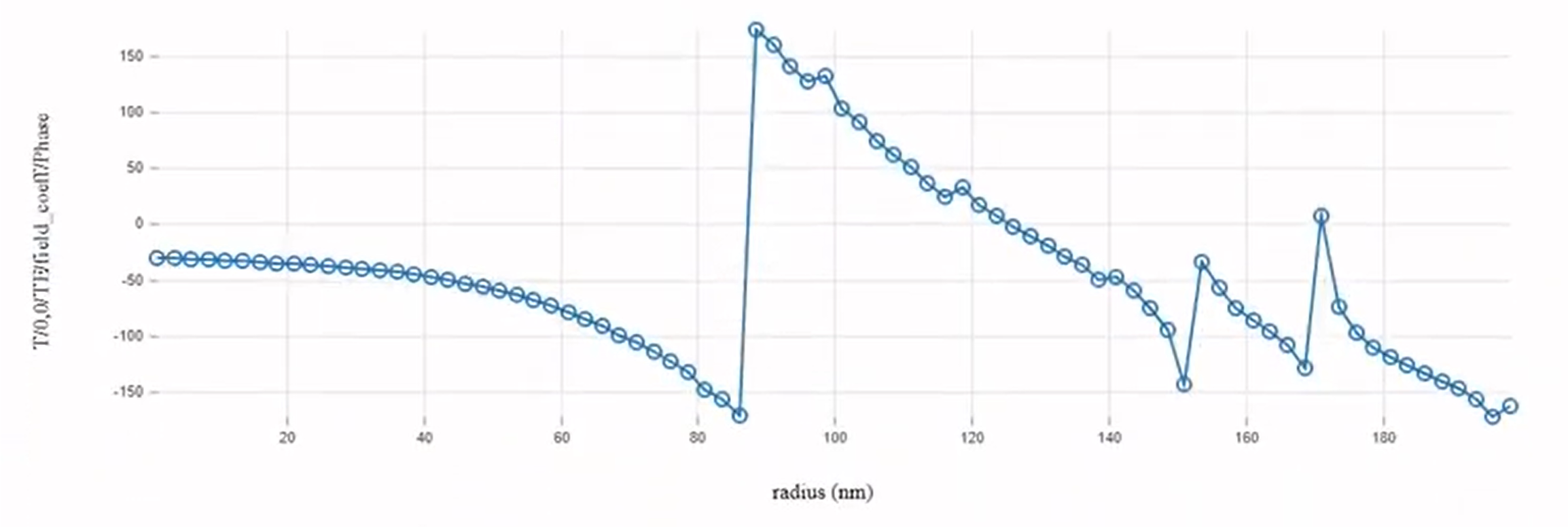

phase vs pillar radius

calculated using RCWA

Pillars from 0-to-2pi phase

are selected and saved in

a meta-atom library

to use as building blocks

for metasurface layout

englarged GDS mask showing

meta-atoms placed at positions

in the metasurface to minimize

target wavefront error

meta-atoms placed at positions

in the metasurface to minimize

target wavefront error

rectangular and cross-shape

meta-atoms placed at each

position on the surface

according to the phase with

the lowest target wavefront

error

meta-atoms placed at each

position on the surface

according to the phase with

the lowest target wavefront

error

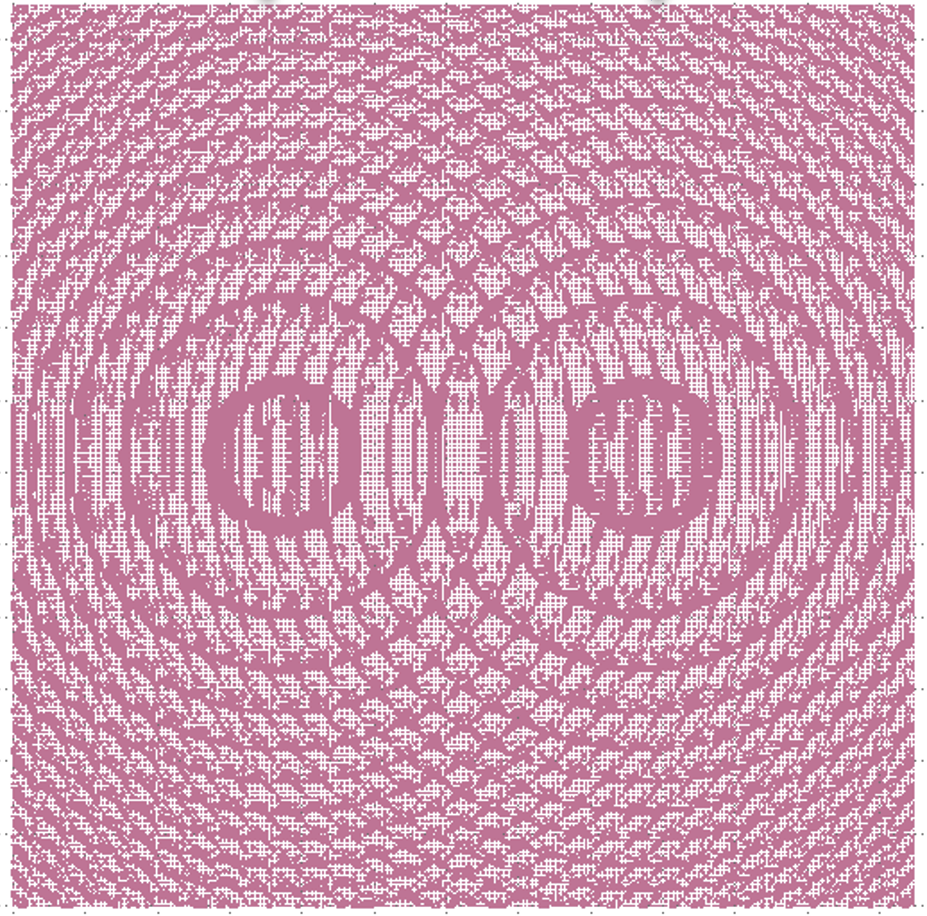

GDS mask showing metasurface

layout with weighted optimization

to split TE and TM polarization

Metalenses are increasingly replacing conventional lenses for imaging, sensing and display applications, because they are flat lenses with many degrees of design freedom that can simplify and reduce the size of optical systems.

Metalenses can control the amplitude, phase and polarization of light. They can be designed for large FOV, achromatic correction, polarization sensing and control and complex wavefront patterns.

There are several ways to fabricate metalenses, depending on the application, the materials and the production facilities.

E-beam lithography by scanning an electron beam is typically used for low-volume laboratory applications.

Photo lithography, using a mask, similar to semiconductor manufacturing, is for high volume applications.

Nano-imprint lithography is a pattern transfer method which mechanically creates a pattern in a soft material, such as a polymer. The material is then cured by UV light.

Features of PlanOpSim MetaCell program module

Create subwavelength pillars and meta-atom pillar groups.

Metasurface pillar shapes included:

round - polarization insensitive

rectangular - polarization sensitive by rotation

cross - more polarization control by rotation and x, y dimensions

Full wave RCWA Maxwell solver to calculate the phase and transmission

of meta-atoms

Plot heat map showing transmission (in red) vs pillar height and radius

Choose pillar height for maximum transmission across a range

of pillar sizes and for practical fabrication height.

Plot phase vs pillar radius to select pillars from 0-to-2pi phase

to include in a meta-atom pillar group

Store meta-atom pillar groups in a library for convenient metasurface

layout, as described in the next section on the MetaComponent

program module.

The library can contain meta-atom pillar groups with different pillar

shapes for designing complex, multifunction wavefront targets,

for polarization control and for achromatic design by dispersion

engineering.

Ask us for use cases describing polarization control and dispersion

engineering.

Contact us to request RCWA vs FDTD speed and accuracy comparison.

Features of PlanOpSim MetaComponent program module

The MetaComponent program is for importing near-field and far-field

targets, conveniently laying out metasurface structures using the

meta-atom library created in the MetaCell program, exporting GDSII

fabrication files and exporting metasurface designs to Zemax.

Near-field design - two ways:

Input Zemax wavefront surface response (binary2 surface)

Input near-field phase as an analytical expression, in a

Python script to create a customized wavefront

Far-field design - and IFTA

For far-field design a target pattern can be imported, such as a JSON

image file.

Iterative Fourier Transform Algorithm (IFTA) is used to create

metasurface phase designs from a far-field pattern.

IFTA starts by creating a random phase distribution

in the near-field, based on far-field amplitude input.

The projected pattern is evaluated against the target, and each

iteration improves the phase design until a desired pattern

is developed.

It takes PlanOpSim just seconds to develop, evaluate and improve

mutiple metasurface phase designs.

Parameter sweep

The Parameter Sweep in PlanOpSim is used to optimize designs for

best performance, based on design criteria, and for fabrication

tolerance analysis.

Minimum and maximum ranges for each parameter can be

specified, as well as the number of steps to vary in each range.

Parameters can be varied linearly or randomly.

The Parameter Sweep also makes it easy to see how performance

changes when varying such parameters as wavelength

and angle of incidence.

Results, including spot size, spot location and wavefront can be

shown quickly, and they can be viewed dynamically using a

separate slider bar for each variable.

Export GDSII fabrication files

The finished metasurface design is used to export a GDSII

fabrication file.

Shown on the left are three examples of GDSII masks.

round polarization-insensitive pillars

both rectangular and cross pillars

weighted optimization to split TE and TM polarization

and focal spot locations

Click on each image to enlarge it.

Zemax Import

Importing Zemax binary 2 files into PlanOpSim for metalstructure

applications extends Zemax ray tracing to fully vectorial physical

optics modeling and physical structure designs.

Types of User Licenses

PlanOpSim software is available for online operation or with a dongle for

local operation.

User licenses can either be permanent or renewable subscriptions.

Subscription user licenses can reduce initial cost, offer longer, more

thorough software evaluations or provide practical solutions

for short-term projects.

Subscription user licenses can be converted to permanent licenses

layout with weighted optimization

to split TE and TM polarization

PlanOpSim Metalens Simulation and Design Software

Metalenses are increasingly replacing conventional lenses for imaging, sensing and display applications, because they are flat lenses with many degrees of design freedom that can simplify and reduce the size of optical systems.

Metalenses can control the amplitude, phase and polarization of light. They can be designed for large FOV, achromatic correction, polarization sensing and control and complex wavefront patterns.

There are several ways to fabricate metalenses, depending on the application, the materials and the production facilities.

E-beam lithography by scanning an electron beam is typically used for low-volume laboratory applications.

Photo lithography, using a mask, similar to semiconductor manufacturing, is for high volume applications.

Nano-imprint lithography is a pattern transfer method which mechanically creates a pattern in a soft material, such as a polymer. The material is then cured by UV light.

Easy to use

Optical engineers can work efficiently with PlanOpSim metalens simulation and design software,

because it was developed specifically for metalens applications. The workflow is logical and intuitive for metalens

simulation and design.

PlanOpsim is the only optical design software that includes a graphical user interface for all the steps in designing metalenses. This includes: creating meta-atoms and substrate structures, storing them in libraries, creating near-field or far-field targets, laying out metasurfaces, optimizing final designs and exporting GDSII fabrication files.

It is easier to learn and use than software with scripts or a combination of scripts and a graphical interface.

Contact us to request a competitive workflow comparison

Both new and experienced metalens designers can easily modify configurations (e.g. materials, pillar shapes, dimensions, incident light) for performance comparison, and they can dynamically change multiple variables for optimization, tolerancing and manufacturability.

PlanOpSim is your source for both software and expert support by a team that specializes in metalens design and applications.

PlanOpsim is the only optical design software that includes a graphical user interface for all the steps in designing metalenses. This includes: creating meta-atoms and substrate structures, storing them in libraries, creating near-field or far-field targets, laying out metasurfaces, optimizing final designs and exporting GDSII fabrication files.

It is easier to learn and use than software with scripts or a combination of scripts and a graphical interface.

Contact us to request a competitive workflow comparison

Both new and experienced metalens designers can easily modify configurations (e.g. materials, pillar shapes, dimensions, incident light) for performance comparison, and they can dynamically change multiple variables for optimization, tolerancing and manufacturability.

PlanOpSim is your source for both software and expert support by a team that specializes in metalens design and applications.

Two program modules.

PlanOpSim software includes two program modules.

The MetaCell program module is for creating pillar structures and substrates, creating meta-atom groups from pillars, storing meta-atom groups in a library for metasurface layout.

The MetaComponent program module is for creating a near-field or far-field wavefront target, creating metasurface designs, optimizing the final design, laying out the metasurface using a meta-atom group from the library and exporting a GDSII fabrication file.

The MetaCell program module is for creating pillar structures and substrates, creating meta-atom groups from pillars, storing meta-atom groups in a library for metasurface layout.

The MetaComponent program module is for creating a near-field or far-field wavefront target, creating metasurface designs, optimizing the final design, laying out the metasurface using a meta-atom group from the library and exporting a GDSII fabrication file.

Features of PlanOpSim MetaCell program module

Create subwavelength pillars and meta-atom pillar groups.

Metasurface pillar shapes included:

round - polarization insensitive

rectangular - polarization sensitive by rotation

cross - more polarization control by rotation and x, y dimensions

Full wave RCWA Maxwell solver to calculate the phase and transmission

of meta-atoms

Plot heat map showing transmission (in red) vs pillar height and radius

Choose pillar height for maximum transmission across a range

of pillar sizes and for practical fabrication height.

Plot phase vs pillar radius to select pillars from 0-to-2pi phase

to include in a meta-atom pillar group

Store meta-atom pillar groups in a library for convenient metasurface

layout, as described in the next section on the MetaComponent

program module.

The library can contain meta-atom pillar groups with different pillar

shapes for designing complex, multifunction wavefront targets,

for polarization control and for achromatic design by dispersion

engineering.

Ask us for use cases describing polarization control and dispersion

engineering.

Contact us to request RCWA vs FDTD speed and accuracy comparison.

Features of PlanOpSim MetaComponent program module

The MetaComponent program is for importing near-field and far-field

targets, conveniently laying out metasurface structures using the

meta-atom library created in the MetaCell program, exporting GDSII

fabrication files and exporting metasurface designs to Zemax.

Near-field design - two ways:

Input Zemax wavefront surface response (binary2 surface)

Input near-field phase as an analytical expression, in a

Python script to create a customized wavefront

Far-field design - and IFTA

For far-field design a target pattern can be imported, such as a JSON

image file.

Iterative Fourier Transform Algorithm (IFTA) is used to create

metasurface phase designs from a far-field pattern.

IFTA starts by creating a random phase distribution

in the near-field, based on far-field amplitude input.

The projected pattern is evaluated against the target, and each

iteration improves the phase design until a desired pattern

is developed.

It takes PlanOpSim just seconds to develop, evaluate and improve

mutiple metasurface phase designs.

Parameter sweep

The Parameter Sweep in PlanOpSim is used to optimize designs for

best performance, based on design criteria, and for fabrication

tolerance analysis.

Minimum and maximum ranges for each parameter can be

specified, as well as the number of steps to vary in each range.

Parameters can be varied linearly or randomly.

The Parameter Sweep also makes it easy to see how performance

changes when varying such parameters as wavelength

and angle of incidence.

Results, including spot size, spot location and wavefront can be

shown quickly, and they can be viewed dynamically using a

separate slider bar for each variable.

Export GDSII fabrication files

The finished metasurface design is used to export a GDSII

fabrication file.

Shown on the left are three examples of GDSII masks.

round polarization-insensitive pillars

both rectangular and cross pillars

weighted optimization to split TE and TM polarization

and focal spot locations

Click on each image to enlarge it.

Zemax Import

Importing Zemax binary 2 files into PlanOpSim for metalstructure

applications extends Zemax ray tracing to fully vectorial physical

optics modeling and physical structure designs.

Types of User Licenses

PlanOpSim software is available for online operation or with a dongle for

local operation.

User licenses can either be permanent or renewable subscriptions.

Subscription user licenses can reduce initial cost, offer longer, more

thorough software evaluations or provide practical solutions

for short-term projects.

Subscription user licenses can be converted to permanent licenses

To contact HMS Technology Sales for more information

click here